When you’re first getting into developing film and making prints, you might not be reaching for the chemicals all that often. Most photographers take much fewer photographs in the winter, so it could even take an entire six months before you’re yearning to get back to developing film. And it’s always possible to end up going through a lull at one point or another. And the worst thing to come back to is a pile of useless, expensive, environmentally damaging chemicals.

But why do these chemicals spoil? Our homes are filled with hundreds of chemicals that don’t expire over time, so what makes these different?

Film developing chemicals are typically difficult to store for two main reasons: developer and fixer are both reducing agents, meaning they react with oxygen. This means to make them store over a long period of time, the solutions have to be stored in ways that limit their exposure to air.

I’m lucky enough to have spent some of my post-secondary education in a chemistry lab. So I’ve learned a variety of ways to keep chemicals lasting as long as possible — both with and without fancy lab tech. It’s tricky at first, but it doesn’t have to be expensive.

How do I make chemicals last longer?

Film developing chemicals will last their longest when mixed with distilled water, and stored without any pockets of air in the bottles. They should be stored in cool conditions away from sunlight.

When you’re mixing chemicals, tap water will contain different contaminants depending where in the world you live. Because of this, the film developing chemicals will almost always last longer using distilled water, which is completely free of any minerals. That said, In most cases, tap water won’t seriously degrade the chemicals over the short term.

If you plan to use the developer or fixer within a month of two, tap water won’t be much of an issue so long as the bottles are air tight. Be sure to use cold tap water, as hot or warm water may contain more contaminants built up over time inside the hot water heater. Not only does the hot water affect the chemicals, it can also leave spots on your film when it dries.

For printers using large trays, it is also possible to re-use the chemicals over time. However, dust and other particles often find their way into the chemicals. The best solution I’ve found is to filter them out using bleach-free cone-shaped coffee filters. The cone shape fits perfectly into a funnel for easy pouring, and the unbleached versions ensure that no left-over bleach leaches into the solution.

What’s the best container to store film development chemicals?

I’ve used a number of different solutions for storing film chemicals, from plastic bottles designed for it, to simple and commonly available beer growlers.

Almost every store that sells film chemicals will have some plastic bottles designed for storing chemicals. They’ll range from brown regular plastic bottles with a white-board style sticker on them for labeling, to large bottles that have accordion shapes on the side to compress the air out of the bottles. Because oxygen is the enemy of film developing chemicals, the accordion-style bottles are a really good option for large 5-Litre (1 gallon) batches of chemicals that are typical with powdered chemicals. Especially if you find one that has a good seal and a handle, it’ll keep the chemicals fresh for much longer than a standard plastic bottle.

But even these plastic bottles do have a large flaw. If the seals don’t break over time, oxygen will slowly seep through the plastic and ruin the chemicals. It’s a slow process, but it is noticeable. For example, this is the reason why a bottle of Ilford Rapid Fixer must be used within two years of production — even if the bottle is completely sealed. This is especially true if there’s even a little pocket of air on the top of the accordion bottle. That pocket can slowly allow air through, and you’ll come back a week or two later to see the bottle is no longer compressed.

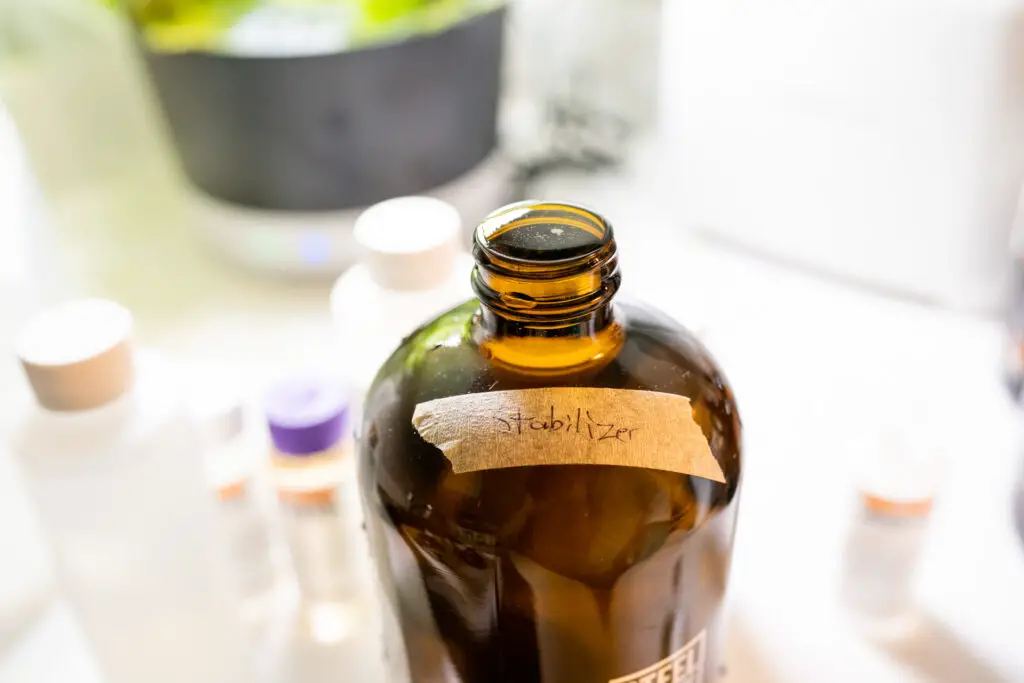

Because of that, I’ve had the best luck with glass bottles filled completely to the brim. I personally use growler bottles because they’re available and come with fresh local beer. These bottles seal extremely well when completely filled, and the different designs help me to differentiate the chemicals when developing.

You’ll know you have the bottle perfectly full when there’s a bit of water over top of the rim of the bottle. If a bead of water doesn’t come down the side when you screw on the cap, add a bit of distilled water to the mix until it does. Using this method, I’ve had a diluted fixer solution last longer than the undiluted solution in the plastic bottle.

Do Liquid or Powder developers last longer?

Because oxygen can seep through plastic bottles, liquid solutions are not completely safe. Even if the bottle is still sealed, it can become oxidized over time. Powdered developers don’t have this problem. The reducing agents in the developer are inert until they’re dissolved in water. Meaning a bag of powdered D-76 from the 1930s should theoretically still make a viable developer. Assuming it was stored dry for its 100-year journey into your fateful darkroom.

But once these chemicals are mixed, they have a much shorter shelf-life than their liquid compatriots. Assuming the mixing is completed perfectly without contamination and at the exact right temperature, it will last just as long. But the truth is, that rarely happens. Mixing dry developing chemicals is difficult. Put the powder in water at low temperatures, and it’ll for photo-ruining clumps like no-name brand mac and cheese.

The best option is to boil distilled water to the right temperature and hope there aren’t contaminants built up in your kettle, or use a Sous Vide to heat the water to the exact required temperature in the technical data sheet.

Once a bottle of liquid developer or fixer is opened, it tends to have a longer shelf-life than the powdered versions. That’s because the labs where these chemicals are mixed are designed up to the highest contamination-free standards. Their chemicals need to get to their customers’ hands and still be functional. So they take great pains to reduce any form of contamination in their facilities.

That said, some developers like Rodinal (Blazinol in Canada) are unlikely to ever go bad because of their stable chemical formulas. It’s a common developer’s joke that rodinal will outlive the shelf it’s stored on. This used to be the same for the syrupy-formula for Kodak HC-110. But the new formulation seems to go back much more rapidly, unfortunately.

Personally, I always use liquid film development chemicals because of their ease of use. They’re much quicker and more dependable than powdered forms. So I’ll continue to use them as long as possible. Learn more about the differences between liquid and powdered developers here.

Can I reuse mixed black and white film developer?

Yes, developer can be reused once or twice after it has been mixed. The number of times that it can be reused changes significantly depending on the type of developer. So its best to check the Technical Data Sheets online to make sure that you’re using the chemicals within their tolerance.

When reusing developers, it’s best to add additional time to ensure the film develops properly. For example, The Ilford technical data sheet for DD-X suggests adding an additional 10% onto the developing time with each additional roll. Take, for example, using DD-X to develop a roll of Delta 3200 at box speed. The first roll requires 9.5 minutes of developing time. So, for the second roll, you’ll add 10%, and develop for 10.45 minutes, or 10 minutes and 27 seconds.

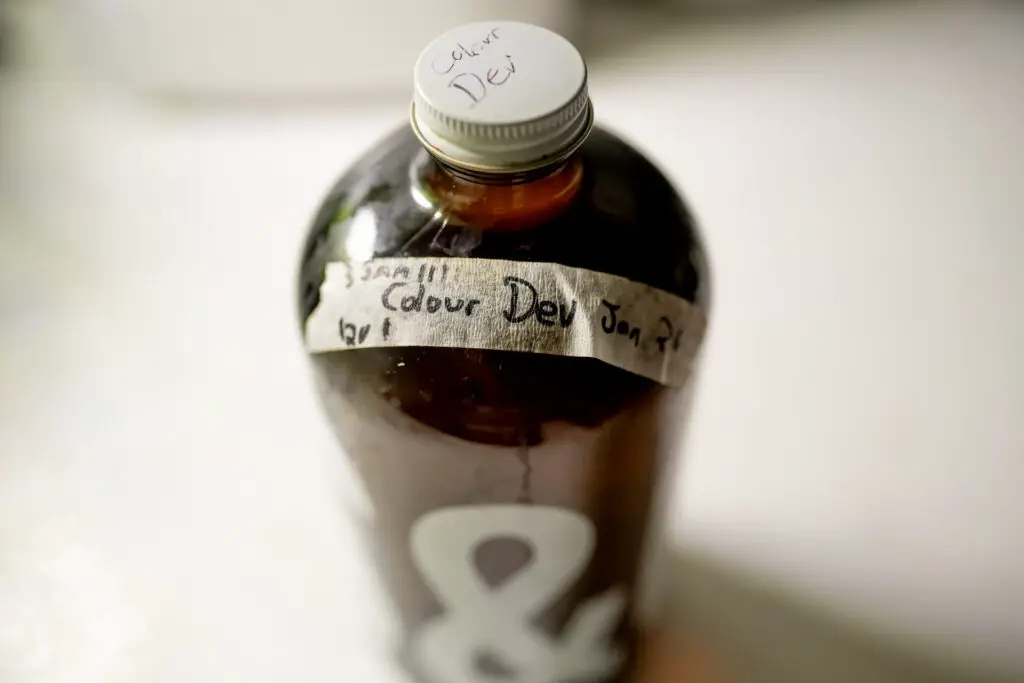

Each developer will have a different amount of time per additional roll. Colour developer, for example, recommends adding 8% additional time for every sheet of 120, or 2 rolls of 35mm film. Always check the technical datasheet for more information. And if you’re going to reuse it, make sure to handle this chemical carefully. Especially if you have eczema, a set of nitrile gloves and a lab coat will go a long way to keeping your skin healthy in the long run.

With that in mind, B&W film developers should not be stored after they have been mixed. Even if they’re mixed with distilled water (which isn’t necessary), they are still likely to go bad overnight. Water contains oxygen, which will oxidize the diluted developers more quickly than non-diluted forms. So it’s best to re-use the developer within a single session if possible, or dispose of it in accordance with local laws.

How many times can I reuse my Stop Bath?

Stop bath is the easiest solution to reuse. I’ve had the same bottle going strong for almost a year now with a couple of small top-ups over time. This is because the stop bath is purely an acid meant to remove the conditions where the developer can continue to act on the film (and ruin the fixer).

Stop bath is basically super-concentrated vinegar with an indicator. Once it loses its acidity, the indicator will make the solution instantly turn a deep purple. This means you can keep re-using the developer until it changes colour. Even if it’s mixed, it doesn’t react with oxygen, and doesn’t need any special care. The sad thing is it’s also the cheapest chemical of the bunch — if only DD-X had that economy, I would be a very happy film developer.

How often can I reuse Fixer?

Fixer is designed to be reused over time. A litre of Ilford Rapid fixer can fix 24 rolls of film without being replenished according to Ilford’s Technical Data Sheet. Beyond that, the fixer may not fix the film to archival standards, meaning the rolls might fog over time as some of the leftover silver reacts to light.

To replenish the fixer, simply add 45ml of fresh rapid fixer solution per roll of processed film. While the bottles of stock solutions only last six months after opening, a solution of fixer can last almost indefinitely if stored correctly with proper replenishment. Over time, though, the fixer will collect a large amount of silver in the solution, which will make it unusable. Silver is also an environmental hazard. So it’s recommended bringing spent fixer solution to a facility that can dispose of it properly. In most cases, you’ll have to bring it to your local waste-disposable center. But quite often, photo labs will take the chemicals back free of charge.

By Daren

Daren is a journalist and wedding photographer based in Vancouver, B.C. He’s been taking personal and professional photos on film since 2017 and began developing and printing his own photos after wanting more control than what local labs could offer. Discover his newest publications at Soft Grain Books, or check out the print shop.

Hi Daren, thanks for the thorough article. I’ve been developing my own film for about a year now at home ever since COVID cut me off from my community college’s darkroom. I’ve got a question however when it comes to isolating the chemicals from oxygen. You said you top it off to the very brim with distilled water, so my question is, after developing like 4 or 5 rolls in a batch and topping it back off with distilled water, how do you accordingly adjust the development times after diluting it? If you do at all, or if I’ve misunderstood the process at some point. I’ve struggled with using my chemicals as economically as possible since moving to doing it all on my own and not having a professor to manage the chemicals for me, so I would really love to up my game.

Hi Finn,

Thanks for reaching out! I’ve also lost the use of my community darkroom because of Covid, so I feel you here!

Unlike color film developers, B&W development chemicals are not typically reused because they degrade more quickly when diluted (48 hours is the maximum time recommended for reuse on most developer technical datasheets). But if you do want to reuse them, the general rule is that you should add 8% to the development time for each roll that’s been developed. So if you have a development time of 5 minutes, and have already developed one roll, you’ll need to increase the dev time to 5 minutes and 40 seconds.

Although this rule might change depending on the developer you’re using. I can help find that specific information for you if you let me know which developer you’re using.

Regards,

Daren